- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

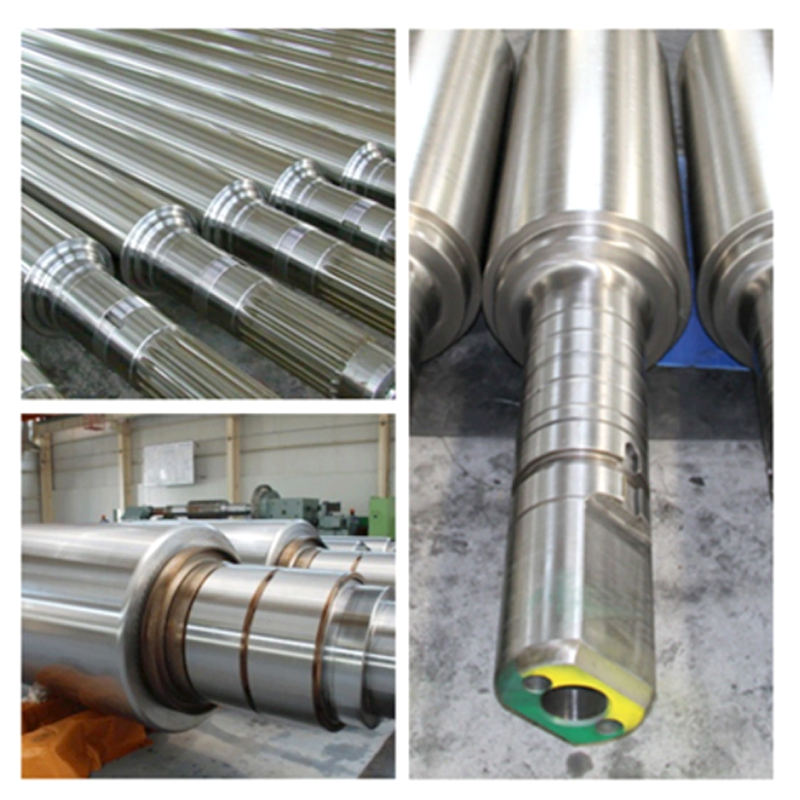

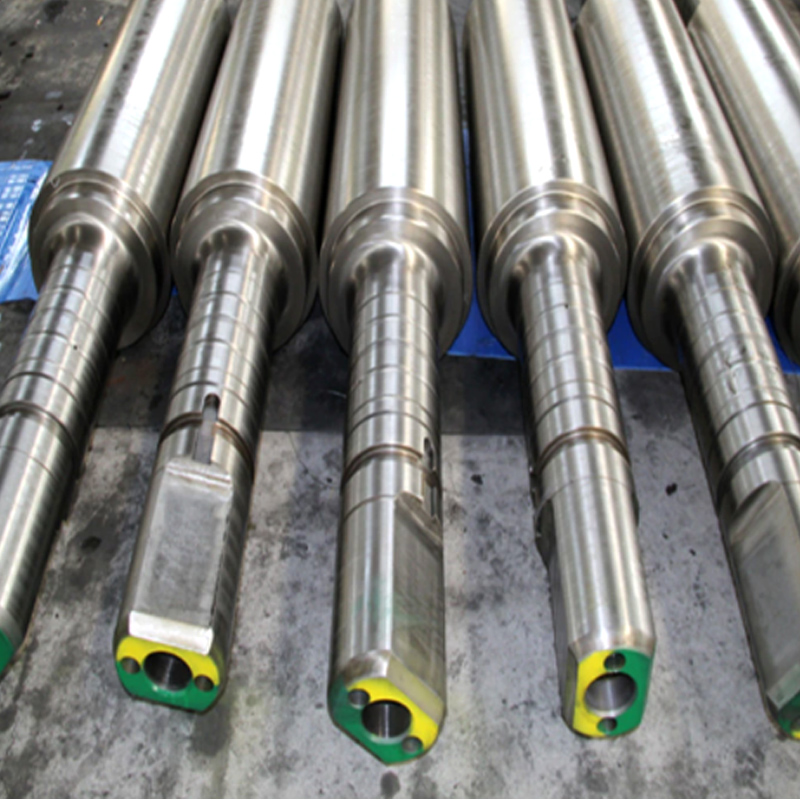

Backup Roll / Intermediate Roll / Work Roll

Tlhaloso ea Sehlahisoa

| Che. | thepa | Khoutu | Ho thatafala(HSD) | Kopo | Matla a Tensile(N/mm2) |

| 1 | tšepe e entsoeng | MC2 | 85/98 | roll roll/intermediate roll/backup roll | 800/1100 |

| 2 | tšepe e entsoeng | MC3 | 85/98 | roll roll/intermediate roll/backup roll | 800/1100 |

| 3 | tšepe e entsoeng | MC5 | 90/100 | moqolo wa mosebetsi/moqolo o mahareng | 800/1100 |

| 4 | tšepe e entsoeng | MC6 | 90/100 | moqolo wa mosebetsi/moqolo o mahareng | 800/1100 |

| 5 | tšepe e entsoeng | 86CrMo | 75/90 | bekapo roll | 800/1100 |

1, Lintlha tsa Sehlahisoa

Meqolo e entsoeng ka maiketsetso e sebelisoa haholo litulong tse ling tse thata tsa leloala le chesang, joalo ka BD

ho ema le ho thunyana ho etsa ka matla a matle ho qoba ho thetheha

likotsi. Ho sa le joalo, e boetse ke khetho e ntle ea ho sebetsa ka leloala le batang la ho roala joalo ka

bekapo roll and work roll.Ts'ebetso eohle e theha ho qhibiliha, ho lahla, ho forging, phekolo ea mocheso ho fihlela machining ea ho qetela le ho paka e tlas'a taolo ea tsamaiso ea boleng ea TANGSHAN WEILANG.

2, Lisebelisoa tsa ho sebetsa

Re na le letoto la lisebelisoa tse tsoetseng pele tsa machining tse fihlelang litlhoko tsa tlhahiso, ho kenyeletsoa mochini oa centrifugal, sebōpi sa maqhubu a mahareng, sebopi sa kalafo ea mocheso, mochini oa ho sila oa CNC oa kantle, mochini o silang oa CNC, mochini o otlolohileng oa gantry, mochini o fetolang le mochini oa sawing.

3, Tlhahlobo ea Boleng

Pele ho romelloa, lihlahisoa tsohle li tla hlahlojoa ka tlhahlobo ea ultrasonic le tlhahlobo ea metallographic ka tieo ho netefatsa boleng.