- Beijing Jounyihong Metallirgya Machine Ltd.

- bjmmec@yeah.net

- +86 15201347740/76 13121182715

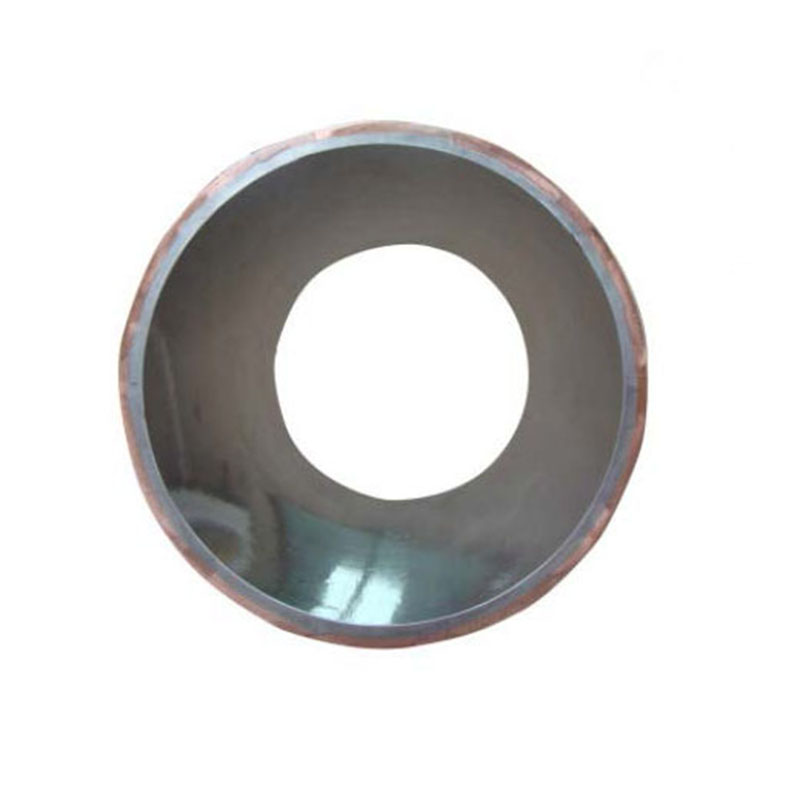

Tšebeliso ea tšepe e qhibilihileng ea CCM ea Sehlahisoa sa Copper Coros

Selelekela sa Product

Butle-butle o tiisa hore tšepe e hlonngoeng ke khetla ea boholo le sebopeho se hlokahalang;

Ka ho kopanya hlobo ke ho tlosa khetla leboteng le sa tsoangoeng le ho qhala tšepe;

✬ Ka ho fetola li-parameter tsa hlobo, ha ho na bofokoli bo kang ho hlolla, ho hlorisa le ho hlakoloa;

✬ e netefatsa hore khetla e sa tloaelehang le khetla e tsitsitseng.

Litlhaloso

Litsi tsa Bohlokoa: Cudhp, Cuag, Cuag, Cuag, Cuagr

✬ Coating Seyer: CR, Nicocr

✬ Round Blank ho φ100mm ho φ1000mmmmmm

| Round Billet Crystallizer Copper Tension | ||

| Karolo ea Case | Radius ea mochini oa casting | Bolelele ba sehlahisoa |

| φ90 | R = 3000-5000 | L = 812-850 |

| φ100 | R = 3000-6000 | L = 812-850 |

| φ1055 | R = 5000-6000 | L = 812-900 |

| φ110 | R = 6000 | L = 812-900 |

| φ120 | R = 5250-8000 | L = 812-900 |

| φ130 | R = 5250-8000 | L = 812-900 |

| φ140 | R = 5250-8000 | L = 812-900 |

| φ150 | R = 5250-8000 | L = 812-900 |

| φ1600 | R = 6000-9000 | L = 812-900 |

| φ180 | R = 6000-10000 | L = 812-900 |

| φ190 | R = 6000-10000 | L = 812-900 |

| φ200 | R = 6000-10000 | L = 812-900 |

| φ210 | R = 6000-10000 | L = 812-900 |

| φ220 | R = 6000-10000 | L = 812-900 |

| φ230 | R = 6000-10000 | L = 812-900 |

| φ280 | R = 6000-10000 | L = 812-900 |

| φ310 | R = 6000-15000 | L = 812-900 |

| φ320 | R = 6000-15000 | L = 812-900 |

| φ30 | R = 6000-15000 | L = 812-900 |

| φ340 | R = 6000-15000 | L = 812-900 |

| φ350 | R = 6000-15000 | L = 812-900 |

| φ400 | R = 6000-15000 | L = 812-900 |

| φ450 | R = 6000-15000 | L = 812-900 |

| φ500 | R = 6000-15000 | L = 812-900 |

E tsepamisitse maikutlo ho moralo, tlhahiso le ts'ebeletso ea lisebelisoa tsa metalluriccal ka lilemo tse 30.

Litlhoko tsohle tsa bareki li rarolla litlhoko tsa hau hang-hang ka lekhetlo la pele ho fetela ho hlahisoa ha bareki.

Haeba bothata bo etsoa ke rona, re tlameha ho e rarolla.

Sehlopha se holimo sa tekheniki, se tsoetseng pele ka mokhoa o tsoela pele ho tsamaisa theknoloji le tšenyo ea boleng ba mahlale ho u fa lihlahisoa le tšebeletso e tšepahalang.